CYCLONE™

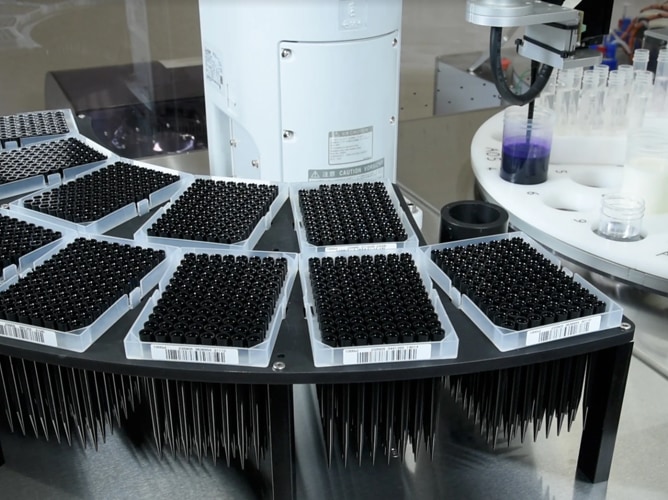

Automated Liquid Sample Processor for Testing of Raw Materials, Semi-Finished, and Finished Products

Product Overview

The CYCLONE™ fully automates pour plating, spiral plating, and sample spreading for the Food Safety industry. The system is capable of automatically managing a high throughput of sample dilutions and handles multiple molten agars simultaneously.

- Automates pour plating, spiral plating, and sample spreading for the Food Safety industry.

- Capable of automatically managing a high throughput of sample dilutions

- Can handle multiple molten agars simultaneously

The CYCLONE™ is ideal for laboratories wanting to increase their accuracy, reproducibility and productivity, while also decreasing operational costs with labor savings and by moving away from expensive film-based agars.

Maximize Labor Efficiency

Maximizes laboratory efficiency and staff productivity by automating manual tasks. More samples can be processed without added headcount.

Reduce Operational Costs

Open media platform, reusable consumables, and precise agar usage lowers costs and minimizes waste

Improve Consistency and Quality

Automates techniques of experienced technicians delivering utmost accuracy and precision for quality results.

Customizable Flexibility for Diverse Workflows

Wide range of modules allows for easy adoption and adaptability to laboratory workflow and needs as they change.

Not Just an Automated Liquid Sample Processor, but a Partner for the Future

Technological innovation is nothing without human collaboration. That’s why, from the installation of the first generation of automated processors in clinical Microbiology to the most recent innovation in instruments for the Food Safety industry, COPAN has continued to encourage input and foster collaboration with the Microbiology community. Around the world, as laboratories adopt automated up-front sample processing, we listen and continuously innovate to provide customized solutions designed to fit the needs of our partners.

Automate Manual Tasks to Unlock Staff Potential

Custom protocol settings allow management of all aspects of plating techniques, including sample volume, mixing duration, dilutions set, and selection of agar type(s) for each sample. The CYCLONE™ addresses many aspects of sample processing such as accessioning, selecting protocols, and labeling plates so laboratory professionals can be re-deployed to higher-level tasks that require their expertise, rather than having to spend the day processing samples.

Flexibility for a Wide Range of Samples Types and Protocols

CYCLONE™ can be configured to perform fully customizable pour plating, spread plating, and spiral plating techniques. The system is a flexible platform allowing for adaptation for the processing of different sample input containers. With the pour plate technique, plates can be routed to the internal cooling chamber to set the agar, allowing for a second overlay agar layer, if needed.

Flexibility for Diverse Workflows

CYCLONE™ is designed as a modular solution for the Food Safety laboratory, where optional modules can be added at any time. The CYCLONE™ open consumable platform and modular design ensures that adopting the CYCLONE™ is easy, and the system will adapt to your laboratory’s workflow and needs as they change.

Multi-Media Module

Allows for seamless transitions between different types of media and maintains up to seven molten agars available simultaneously.

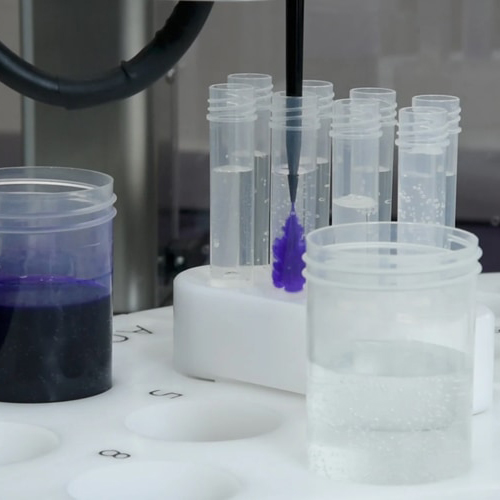

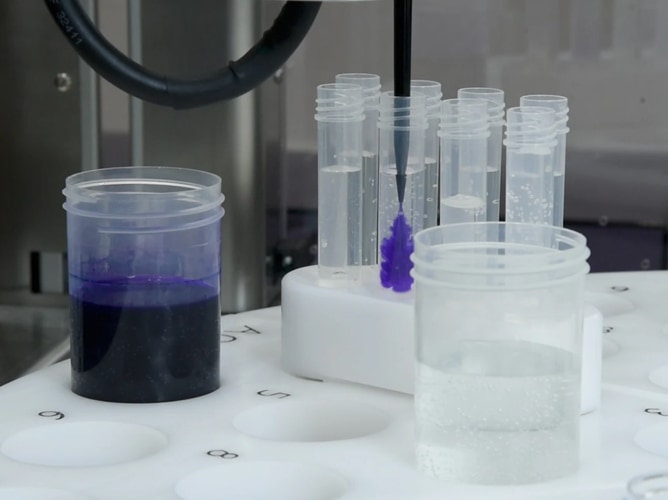

Auto Diluter Module

Automatically measures and aliquots diluent, performing step dilutions for high sample throughput.

Smart Incubation and Imaging Module

Complete plate incubation management that optimizes growth conditions for faster resulting. Built-in imaging and software provide a platform for digital microbiology.

Artificial Intelligence Driven Plate Interpretation Module

Automatically performs colony counts and utilizes algorithms to detect the presence or absence of target pathogens, such as Salmonella, Listeria, or E.coli.

Process Any Liquified Sample

This automated platform is fully customizable, with pour plating, spread plating, and spiral plating techniques that can be tailored to your specific protocols and sample types. Integrated cooling gelation chambers accelerate agar gelling for timely overlay plating when confirmation testing calls for it.

Reduce Operational Costs

CYCLONE™ is an open platform allowing clients to use petri dishes and agar from any supplier so that users can benefit from the most competitively priced materials. The system uses reusable and autoclavable calibrated tubing and caps to minimize consumables costs and waste. CYCLONE™ dispenses consistent and precise agar volumes, preventing waste in the laboratory.

Consistently Reliable, High-Quality Testing

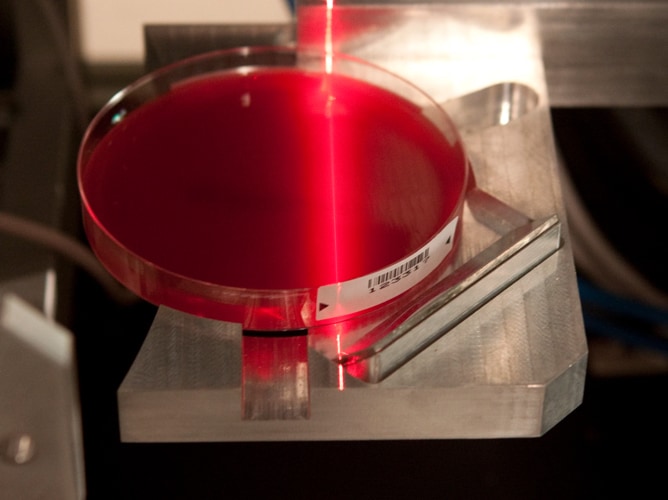

CYCLONE™ is designed to mimic the activities of an experienced technician, diluting and plating samples with high precision and reproducibility that is only possible with automation. Specialized liquid-sensing conductive pipette tips confirm the presence of the sample and ensure sample uptake and delivery.

Reduce Contamination

The design of the CYCLONE™ includes many features that reduce testing variability. The robotic pipettor never passes over another open sample container thus preventing risk of cross contamination. HEPA filtered workspace inside CYCLONE™ continuously circulates clean air within the instrument to protect sample and test integrity. Built-In UV lights and easy-to-clean surfaces ensure proper environmental hygiene.

Barcode Driven System, Providing Unparalleled Traceability

The CYCLONE™ enables bidirectional communication with any LIMS for automated sample identification, protocol selection, and status reporting. Fully barcode-driven, it accesses bottom-labeled tubes, cups or rigid containers for complete sample traceability. Both specimen containers and agar plate labels seamlessly reconcile in the LIMS. By recording every processing step, the CYCLONE™ guarantees laboratories will never lose track of samples or lack actionable data on their status.